Industries & Applications

Perforated materials are used in a number of different applications and industries for a variety of reasons. Used as screens, filters, shields, and guards, perforated materials can control the passage of air, liquid, light, solids, heat, electromagnetic waves, and sound waves.

In addition to OEM applications, perforated materials are also used for their aesthetics in architectural and design applications such as facades, fixtures, and privacy panels.

Knowing how perforated materials are typically used in industrial, architectural, and design applications may help you determine whether or not you have a use for it. Assuming you do, the issue then becomes which pattern to use. While this may be as simple as choosing one that looks a certain way, it can be critical that the perforated material performs a certain way for particular applications (i.e., attenuate a sound frequency, provide a level of electromagnetic shielding, etc.).

For those industries and applications where a certain appearance is desired, we offer our ability to produce more than 4,000 patterns in round, square, slot, hexagon, decorative, and twenty-first century patterns. For those applications where a level of performance is required, in addition to our numerous patterns, we offer literature on tests performed by independent laboratories on some of the most important capabilities of perforated material.

Agriculture

Oil & Gas

Automotive

Appliances

Heavy Industrials

Power Generation

Distribution

Furniture

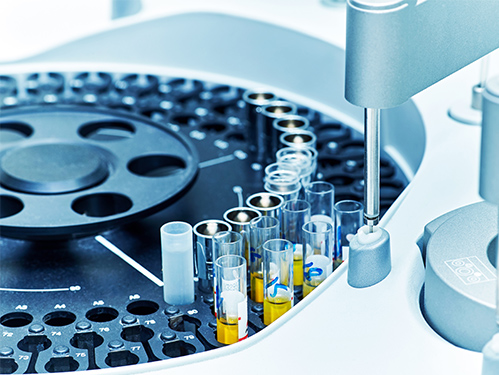

Lab Equipment

Electronic Equipment

Metal Buildings

HVAC

Industrial Conveyors

Architecture

Aerospace

Commercial Kitchens

Diamond Manufacturing is a wholly owned subsidiary of Reliance, Inc.

Site designed and developed by Blair Inc.

Contact Us

Physical address:

243 West Eighth Street

Wyoming, PA 18644

Mailing address:

P.O. Box 4174

Wyoming, PA 18644

Site designed and developed by Blair Inc.